Dimensional Accuracy & Consistency:

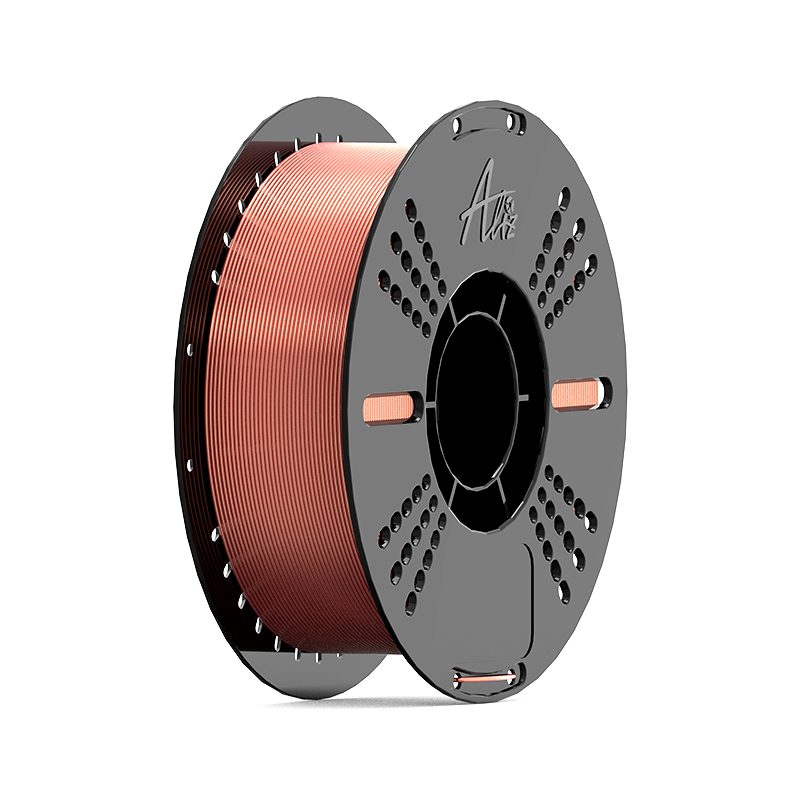

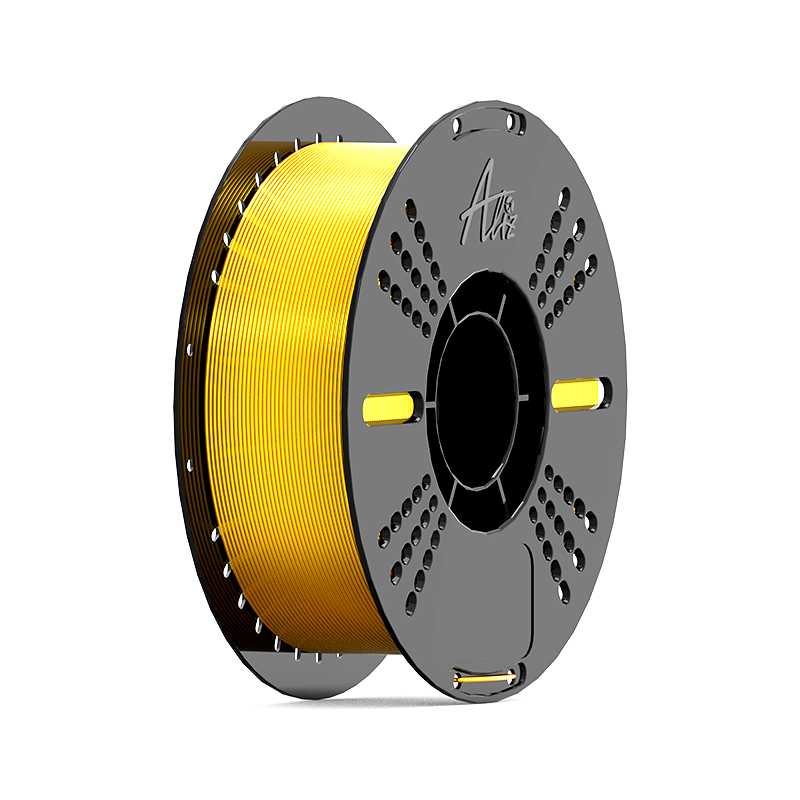

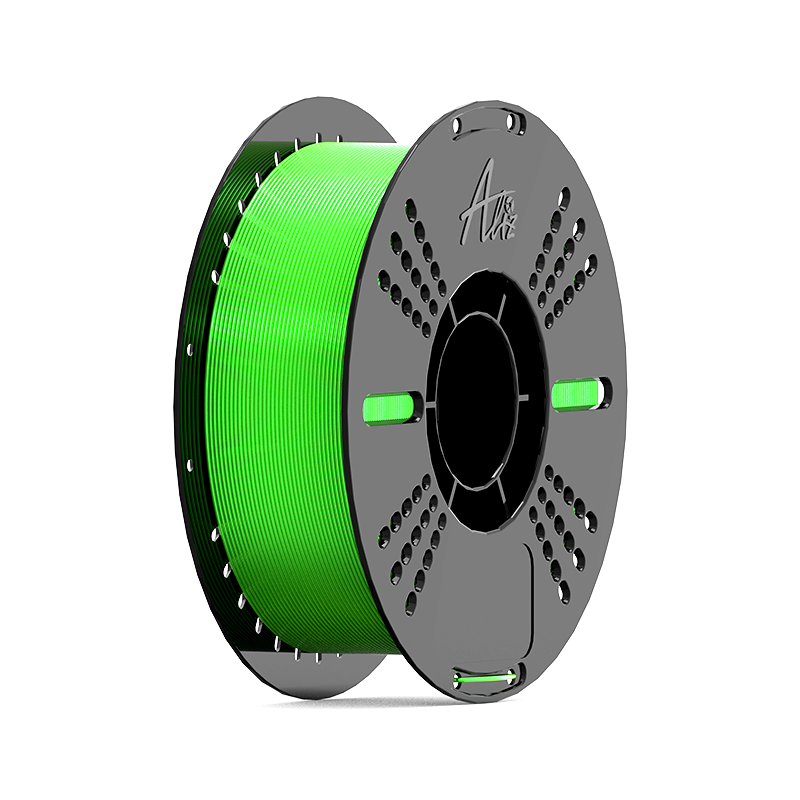

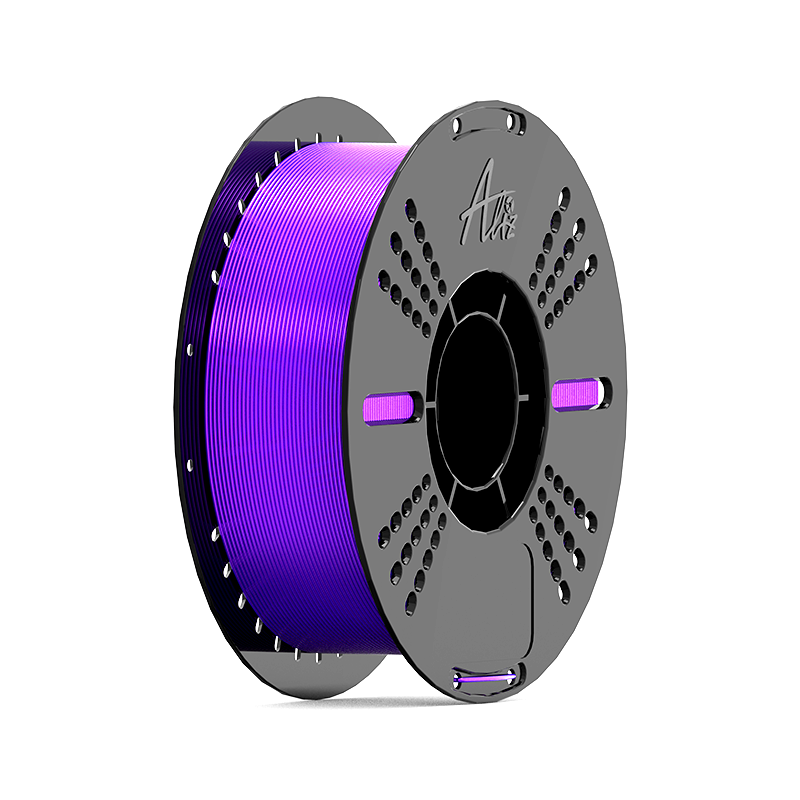

Our premium PLA Silk filament is manufactured using state-of-the-art CCD measurement technology, ensuring precise diameter control throughout production. Each spool maintains a consistent 1.75mm diameter with industry-leading tolerance of ±0.03mm, setting new standards for dimensional accuracy.

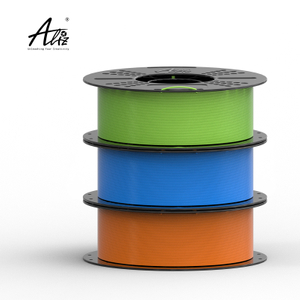

We package our professional-grade filament in convenient 1kg spools (2.2lbs), optimized for extended printing sessions. The standardized dimensions and universal spool design guarantee compatibility with mainstream FDM 3D printers, making it an ideal choice for both professional and hobbyist applications.