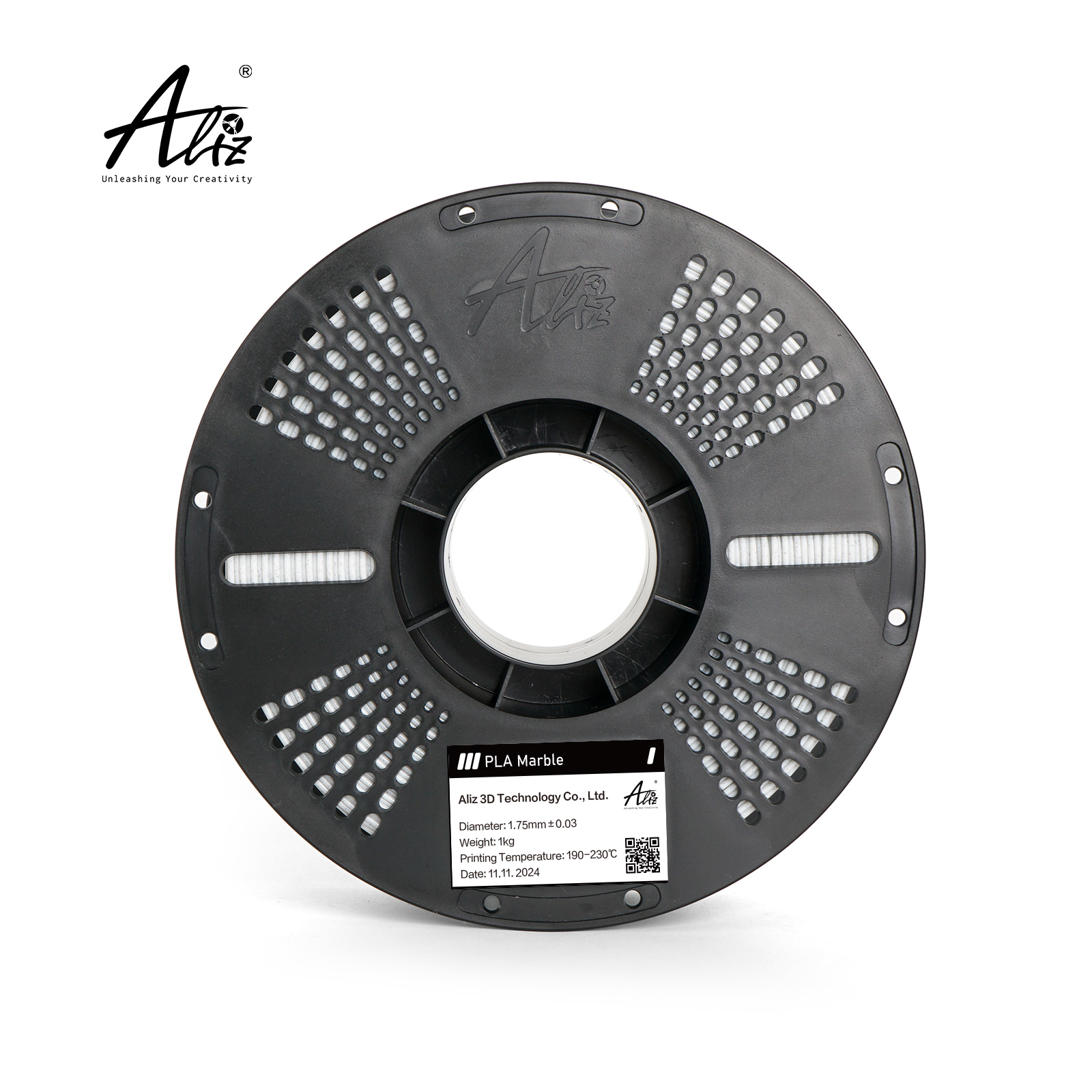

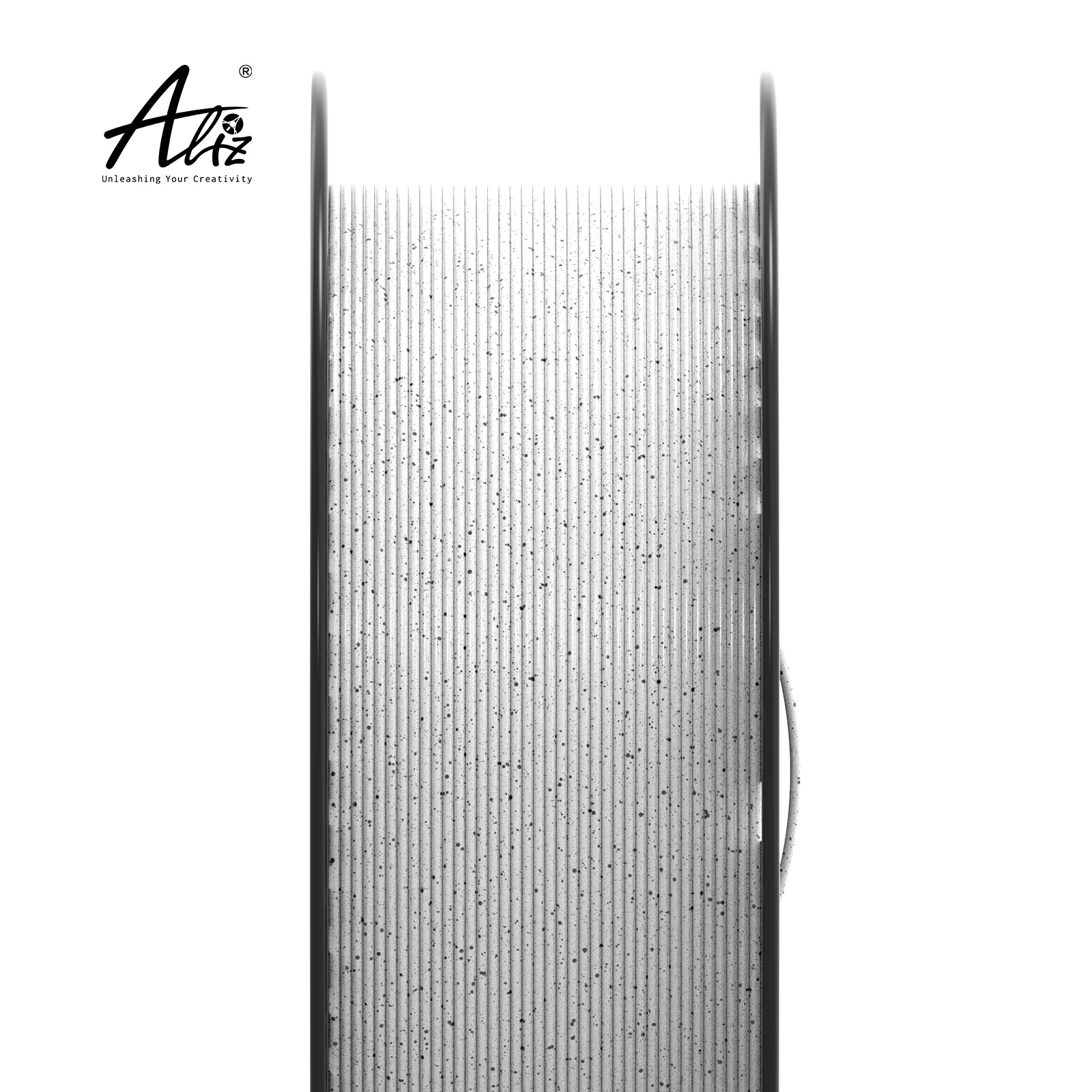

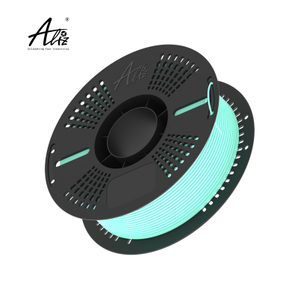

1. Decorative and Artistic Creations

Aliz PLA Marble is ideal for crafting vases, sculptures, art pieces, jewelry, and fashion items such as pendants and earrings. The natural stone appearance and unique texture elevate any decorative or wearable piece, adding a touch of luxury and sophistication.

2. Architectural and Home Decor Solutions

Aliz PLA Marble is perfect for creating architectural models and interior design mock-ups that replicate real stone structures, enhancing presentations to clients. Additionally, it's great for creating home decor items like lamps, candle holders, and pictures frames, bringing a luxurious marble finish to everyday objects.

3. Professional and Educational Use

Aliz PLA Marble is suitable for prototyping in industries such as furniture and construction, where a realistic stone-like appearance is beneficial for client presentations or product development. What’s more it's also excellent for educational purposes, including teaching architecture, geology, and design due to its ability to mimic the natural stone look, and can be used in cosmetic packaging design for high-end products.